Core Capabilities

Organimed’s core capabilities combine formulation insight, manufacturing execution, quality systems, and supply chain coordination to support dietary supplement brands from early development through commercial production.

Our approach is built around consistency, traceability, and real-world manufacturability.

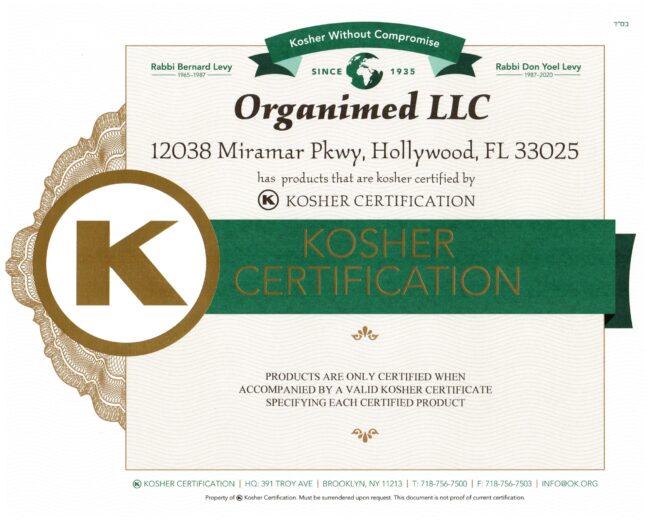

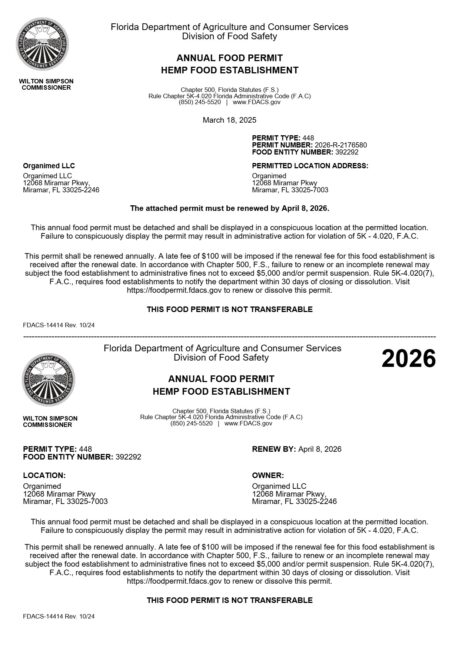

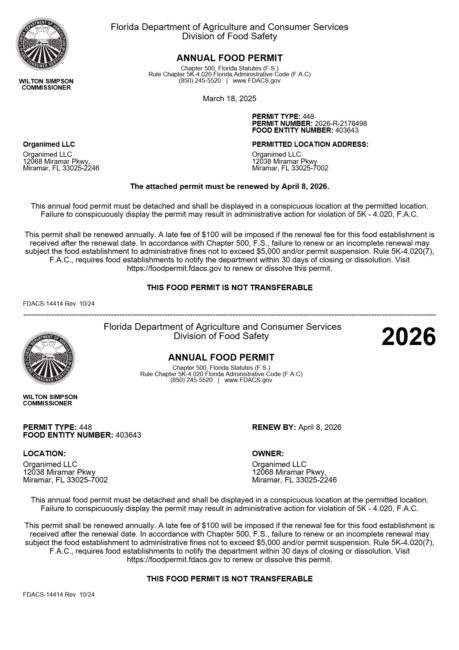

Certifications & Compliance

The entire process complies with US dietary supplement regulations.

Equipment Capabilities

GMP-compliant equipment built to support consistent, scalable supplement production.

Organimed operates with modern, GMP-compliant manufacturing equipment designed to support reliable, scalable dietary supplement production.

Our facility is built to handle a wide range of dosage forms and packaging formats while maintaining strict quality, consistency, and traceability standards. Equipment performance is only as strong as the systems behind it — from raw material control to in-process checks and final packaging validation.

With a fully stocked raw material warehouse and established production workflows, we are able to provide accurate pricing quickly and maintain efficient production timelines.

Our equipment capabilities are designed to support both pilot runs and commercial-scale production, helping brands move efficiently from development to market.

Blending & Mixing

Homogeneous powder blending for consistent dosage and batch uniformity.

Capsule & Tablet Processing

Encapsulation and tablet compression designed for nutraceutical formulations.

Coating & Polishing

Functional and aesthetic coating, polishing, and dust removal to improve product stability and appearance.

Liquid Filling

Precision liquid filling for tinctures, oils, and other liquid supplements.

Stick Pack & Sachet Filling

Single-serve packaging solutions for powders and granulated products.

Bag Filling & Bulk Packaging

Flexible bag and bulk fill options for commercial and wholesale applications.

Shrink Wrapping & Sealing

Secure final packaging for protection, storage, and distribution readiness.

Quality Check Process

Comprehensive quality controls across raw materials, in-process checks, and finished product verification, so you can move forward with confidence.

Supplier Auditing Process

Production QC Process

1

Incoming Material Inspection

Conduct tests on each batch of raw materials for composition, purity, contaminants, etc., and reject any that fail to meet standards.

2

Sampling in production

Ingredient preparation stage

Processing stage

Packaging stage

3

Finished Product Factory Inspection

Conduct comprehensive inspections of the finished product, including sensory, and microbiological tests, and issue a factory report after passing.

Finished Product Testing & Labs

Sampling & Test Planning

Define sampling plans and testing scope based on product type, risk level, and regulatory requirements. Representative samples are collected in accordance with established quality procedures.

Analytical & Third-Party Testing

Conduct required analytical testing internally and/or through qualified third-party laboratories in accordance with applicable regulatory and market standards (e.g., FDA, USP).

Results Review, Documentation & Release

Review test results against predefined specifications, retain complete testing records, and determine material or finished product release based on quality approval and established procedures.